Swiss-Turn Gang tool type ML428

Model

ML-428

Max. turning dia.

42mm

Max. turning length (Rotary)

300mm

Max. turning length (Fixed):

340mm

Max. turning length (Non guide bush)

105mm

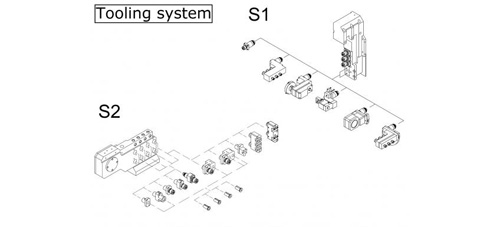

OD tooling holder

6pcs

ID tooling holder

5pcs

Cross live tooling holder

3pcs(ER-20)

Cross live tooling holder

2pcs(ER-16)

Face live tooling of sub spindle holder

8pcs(ER-16)

Sub spindle aside drilling tooling holder

2pcs

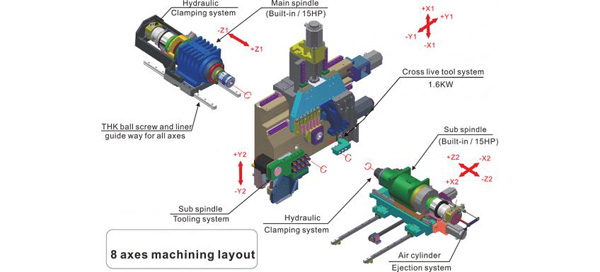

No. of axis controls (with C axis)

8pcs

C axis control minimum

0.001°

Max. main spindle speed

6000rpm

Max. sub spindle speed

6000rpm

Rapid traverse of X1/X2/Z1/Z2/Y1

30M/min

Rapid traverse of Y2

20M/min

Main spindle motor

11KW

Sub spindle motor

11KW

Main spindle cooling

Oil cooling

Sub spindle cooling

Oil cooling

Main spindle clamping system

Hydraulic

Sub spindle clamping system

Hydraulic

Cross live tooling motor

1.6KW / 6000rpm

Face live tooling motor of sub spindle

1.4KW / 6000rp

Lubrication tank

2L

Air compressed pressure

0.6Mpa

Air compressed flow

10L/min

Machine dimension (L x W x H)

2945 x 1650 x 2130mm

Coolant tank

270L(100%)

Weight

4450kgs

Standard accessories:

1. Parts catcher

2. Parts conveyor

3. LED 3 color alarm light

4. LED working light and spindle room light

5. Standard tools (Hex. and open-end wrench set)

6. Collect wrench set

7. Guide bush wrench set

8. Tool box

9. Coolant supply system

10. Coolant tank (270L/100% full)

11. Lub. oil for liner and ball screw

12. Lub. oil for cross and face live tool

13. Main/sub spindle oil cooling system

14. Sub spindle part ejection by air cylinder

15. Transformer

16. Chip conveyor with cart

17. Coolant check device (electrical type)

18. Machine base blocks(6sets)

19. Collet position pin(2pcs)

20. Collet spring(2pcs)

21. Part ejection head

22. Tool life management

23. Machining program execution by hand wheel