CNC Multi-Slide Auto Lathe

Model

ML-NT36S

ML-NT42S

ML-NT51S

ML-NT65S

Capacity

Collet bar (through bore)

36mm(1.42”)

42mm(1.65”)

51mm(2.00”)

65mm(2.56”)

Max. turning length

130mm(5.12”)

Spindle

Spindle center height (approx.)

1000mm(40”)

Collet chuck type

F42 (36mm)

F48 (42mm)

F58 (51mm)

F72 (65mm)

Spindle motor

13.5KW(18HP)

Max. spindle speed

6000rpm

5000rpm

4500rpm

4000rpm

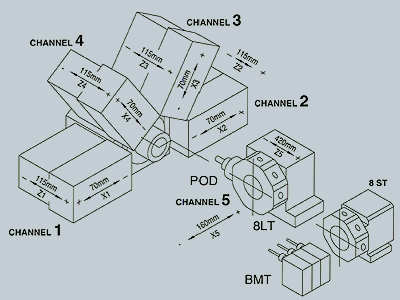

Compound slide

Cross slide travel (x-axis)

70mm (2.76”)

Longitudinal slide travel (Z-axis)

115mm(4.53”)

Rapid traverse, X / Z-axis

X: 15M/min, Z: 15M/min

Working feed rate,

X/ Z-axis

5M/min

Resolution

0.001mm(0.0001”)

Tool turret slide

Numbers of tool position

Basic 8 positions+ Extra tools

Tool shank type

VDI-30x55

Cross slide travel (X-axis)

160mm(6.3”)

Longitudinal slide travel (Z-axis)

400mm(15.8”)

Turning tool section

16mm Sq. (5/8” Sq)

Indexing time

0.28sec/180° -0.6 sec

Sub spindle power

5.5KW(7.4HP)

Sub spindle speed

3000rpm

Overall dimensions

2580*2038*2050mm

Machine weight

3300kgs

Hyd. Tank capacity

30L

Hyd. Pump motor

1KW

Coolant tank capacity

180L

Coolant pump (1)

0.75KW

Coolant pump motor (2) 70kg/cm2 max.

2.2KW

Lubrication capacity

2L, 10cc/11min

Total power required

25KVA

Standard accessories:

- Spindle-collet chuck system(standard).

- 48-position spindle dividing system.

- 8--position servo tool turret (with tool driven)

- Air blow , coolant & hydraulic system

- Automation lubrication system

- Bar loader interface

- Front door interlock and work lamp

- Tool box & tool kits

- Control cabinet heat exchanger

- Pick-off device

- Back machining toolhoiders

- Workpiece belt conyeyor

- Oil mist collector.

Optional accessories:

- Spindle-collet chuck (extra).

- Air live tool unit

- Hydraulic live tool unit

- Chip conveyor with cart ( screw / pallet type)

- Automatic bar loader

- Servo driven live tool unit

- 8-Position turret for back machining.